BREMBO

- Home

- >

- Products

- >

- Brand List

- >

- Brembo

The upgrade within reach of every car.

Designed and tested for predominantly performance-oriented street use, Brembo Sport brake pads represent the first upgrade level for any braking system. These products have been created for drivers with sporty ambitions and, more generally, for anyone who wants to maximise the potential of their car.

Tested to the highest levels on the track with decelerations from 270kph (168mph) the HP2000 material is capable of operating in the most demanding conditions.

With excellent cold performance & bite, high resistance to fade, frictional stability throughout all operating conditions, reduced pad & disc wear and low dust levels, the all new HP2000 friction material offers significant advantages over its rivals.

Designed to be a direct replacement for the Original Equipment (OE) pads the Brembo sport pad comes with the exact same specification as the OE pad including (where applicable): fitted wear leads, slots for separate wear leads and anti-rattle clips with the added benefit of anti-noise shims on every pad.

Combine all of this with competitive pricing and UNECE R90 approval across the full range (making them street legal) and you get a true high performance brake pad fit for the road.

The one-piece slotted or drilled discs of the Brembo High Performance Sport range are available for all most widely sold vechiles. Compared to the Grand Turismo (GT) and Grand Turismo Racing (GT-R) systems, the Brembo High Performance Sport Range offers value for money combined with upgraded stopping power.

Reliable on the road, superior on the track.

The discs of the Brembo Sport range are ideal for enthusiasts who use their vehicles for both normal road use and more performance-oriented driving. With their advanced characteristics, these discs combine the advantages in terms of durability of the best street discs with superior performance suitable for moderate track use.

For greater versatility and to increase their ability to withstand extreme stress, Brembo Sport brake discs are made from high-carbon cast iron for improved thermal and mechanical resistance. They also feature exclusive pillar venting technology, which improves cooling capacity and increases resistance to cracking caused by thermal shock by over 40%. Cross-drilled and slotted finishes are designed and executed with meticulous precision. These holes or slots in the braking surface help dissipate heat and eliminate brake dust and gases.

Every Brembo product is designed in relation to the specific performance requisites. The discs of the Sport range are specifically designed to minimise thermal distortion and disc warping even in the most severe operating conditions. As a result, they ensure outstanding braking power in both everyday traffic and the most extreme high performance driving, yet are easily accessible to all enthusiasts.

Brembo High Performance Sport Discs work with any stock car and does not require any modifications. These discs are the same size as the original equipment parts and have been specifically designed for total compatibility with the standard calipers, wheels and all other original components of the vehicle.

The floating disc system reduces unsprung mass, for improved handling, and thermal stress. The mounting system is engineered to permit a greater degree of both radial and axial float.

Immediate, Consistent Braking in All Conditions

The unique cross-drilled or slotted finish is another exclusive Brembo feature which improves braking consistency by dissipating the heat generated and gas released as the pads come into contact with the discs, keeping the pad surface both cool and clean. Both cross drilling and slots interrupt the water film forming when driving in the wet for improved brake response. This effect is most evident with cross-drilled discs, due to the different solid/hollow ratio of the surface and the possibility for water to flow through the ventilation holes.

Eye-Catching Looks and Total Compatibility.

All the discs of the Sport range are zinc plated, which improves corrosion resistance and also gives the car a more aggressive look.

In spite of their exclusive characteristics, the Brembo Sport discs are the same size as the original equipment components, are fully compatible with the standard calipers, wheels and other components of the vehicle, and are also simple to install. However, all high performance Brembo discs are more durable and offer greater comfort if used in conjunction with the appropriate Brembo pads.

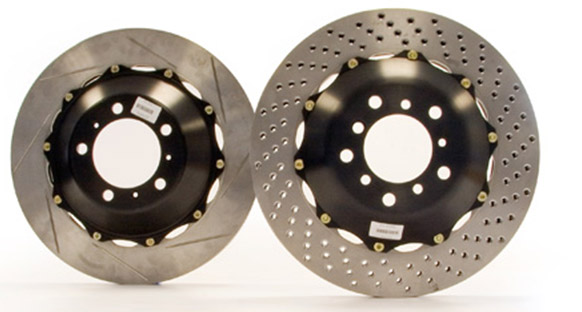

Available as drilled or slotted versions.

The New range of Brembo Turismo 2-piece discs are designed to be a direct replacement of the original fitment discs, using the standard calipers. Much like the discs included in the Gran Turismo kits, the range of Turismo discs are manufactured using high-carbon cast iron, to improve thermal capacity and frictional properties.

Turismo discs are made up of 2 pieces: thermal high-carbon cast iron rotor and a billet aluminium bell. The 2 piece construction using a billet aluminium bell means that the overall unsprung weight of the vehicle is reduced, improving ride quality and handling. Turismo discs are also "floating", which allows for thermal expansion and contraction under braking whilst keeping thermal stresses to a minimum. Through the use of specially designed "spring" bushes, noise is also kept to a minimum as the springs damp-out a lot of the vibrations between the bell, which is fixed to the axle, and the rotor, which is allowed to "float" a small amount both radially and axially.

The Turismo kits comprise a pair of 2-piece floating high-carbon cross-drilled or slotted discs and a set of comprehensive fitting instructions. Most discs also benefit from TÜV Certification and Homologation.

The Brembo Grand Turismo (GT) Brake System offers significant advantages over the OE manufacturer's system - advantages far beyond what is simply known as "big brakes".

© 2012-2013 AutoPerformance Philippines Inc. | Website design by thealbert

AutoPerformance Philippines Inc. - authorized exclusive distributor of Brembo S.p.A.

As the braking system's primary function is to dissipate heat, larger, more sophisticated discs are used in order to increase the fade resistance of the system. These discs are directionally vented for enhanced cooling, as well as drilled or slotted for improved consistency, continuously cleaning and refreshing the pad surface.

The Brembo High Performance (HP) Program is the direct result of winning over 200+ World Championships and decades of designing brake systems for the worlds top supercar manufacturers.

Brembo Dominated Motorsports: Formula 1, World Rally Championship (WRC), NASCAR, Champ Car World Series, Indy Racing League (IRL), American Le Mans Series (ALMS), Grand Am Rolex Sports Car Series, Speed World Challenge, and FIA GT Championship.

A Unique Experience

Brembo has a unique relationship working directly with automotive manufacturers to develop high performance braking solutions specifically for your vehicle. You can rest assured that every system designed by Brembo is specifically tuned for your vehicle like no other braking system on the market.

Brembo supplies over 30 automotive manufacturers including Acura, Aston Martin, Audi, BMW, Cadillac, Chrysler, Dodge, Ferrari, Ford, General Motors (GM), Honda, Infiniti, Jaguar, Jeep, Lamborghini, Land Rover, Lexus, Maserati, Mercedes-Benz, Mitsubishi, Nissan, Porsche, and Subaru.

Brembo uses its own foundries in the industrial process, whereby bringing a thorough knowledge of metallurgy to its design know-how which also creates further synergy in the optimization of the production cycle. The research and development phase is flanked by the testing phase which involves static, comfort and road testing and dynamic tests on test benches.

Brembo brakes are manufactured under quality and environmental ISO 9004 and ISO 14000 management standards which puts Brembo in a league of its own in high performance braking.

| System Includes (Per Axle) |

Caliper Construction / Material |

Number of Pistons |

Piston Design / Material |

Caliper Finish |

Disc Design |

Disc Type |

| Calipers, Discs, Brake Lines, Caliper Mounting Brackets, and Brake Pads |

Cast, Aluminum-alloy, Monobloc or 2-Piece |

2, 4, 6, 8 |

Dust Boot and Inner Pressure Seal |

Red, Black, Silver, Yellow |

1 or 2-Piece |

Zinc Slotted or Zinc Cross Drilled |

Effective Range of Brake Systems

Brembo High Performance GT Systems are designed to give you the advanced technology behind Brembo racing systems without compromising the driveability and comfort features of an OE Brembo system.

OEM (Non-Brembo) systems typically use a heavy, low-grade iron rotor and a flexible sliding caliper that severely limit performance.

Brembo OEM systems are superior to non-Brembo OE systems by the use of opposed, multi-piston aluminum fixed mount calipers, and high carbon discs.

Brembo High Performance (HP) GT & GT-R systems are revolutionary in their design and performance, and no other braking company has been able to offer this level of performance, range of configurations, and sheer number of applications. The GT & GT-R systems exemplify Brembo's dominance as a world leader in high performance braking as an OEM supplier to a winning partner in motorsports.

Racing systems are designed for the sole purpose of winning championships without compromise. This pinnacle of performance limits the ability to build in many of the comfort and anti-noise features that are built into Brembo GT and GT-R Systems.

Optimum Braking Performance

The technology and performance of a Brembo brake system is unrivaled by any other product on the market. Each bespoke system is desgined specific to your vechile for maximum performance and "optimum braking performance".

Brembo engineers design each brake upgrade specifically for your vehicle and driving conditions.

Optimum brake balance is achieved by combining Brembo's thorough knowledge of OEM braking systems and use of an unlimited range of caliper, piston, and disc combinations.

Brembo brake upgrades are easy to install and designed to work seamlessly with your vehicle's stock master cylinder, ABS, and traction control system.

THE BREMBO DIFFERENCE: Improved pedal feel, modulation, and control of braking performance from initial application through ABS intervention.

Calipers

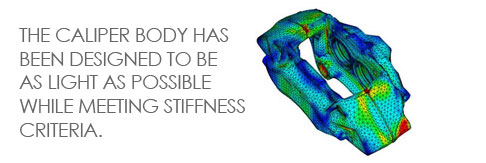

Brembo calipers are designed to be as light as possible while being uncompromised in stretch, durability and reliability.

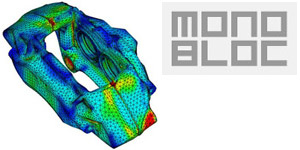

Monobloc: a single integral unit or 1-piece design that optimizes the ratio between mechanical stiffness and weight.

Monobloc: a single integral unit or 1-piece design that optimizes the ratio between mechanical stiffness and weight.

Uncompromised braking solution for those who can't accept "just good enough"

Most OE calipers are of a sliding design, with piston(s) only located on the inboard side of the disc. While this type of caliper is inexpensive to manufacture, it is generally extremely heavy, and inherently flexible under braking, which significantly degrades performance. Conversely, Brembo's calipers are a fixed radial or axial mount design with opposed pistons and constructed from aluminum alloy. Despite being much larger and many times stiffer than the sliding OE caliper, they are also much lighter which benefits overall vehicle dynamics.

Brembo calipers incorporate a twin seal design that restricts dirt and debris from entering the caliper body and contaminating the brake fluid.

This extends caliper life by protecting the pistons and internal pressure seals and prevents the need for maintenance.

Brembo calipers undergo a strict homologation process which exceeds the requirements set by OEM manufacturers.

Caliper Mounting Brackets

All Brembo caliper mounting brackets are designed vehicle and system specific. They are precision milled from superior quality billet materials to ensure a precise fit and meet the strength requirements of high performance driving conditions. Brembo brackets are also further analyzed and tested to ensure fatigue life.

Brembo caliper mounting brackets are also anodized to provide an attractive finish.

Each Brembo system includes all necessary hardware for ease of installation (please read instructions prior to installation).

Discs

1-Piece Discs

One piece rotor systems offer a cost effective solution to the high performance brake upgrade. Includes oversized calipers and rotors for increased brake torque and thermal capacity. These performance upgrades are available for many European, domestic, and import vehicles.

2-Piece Discs

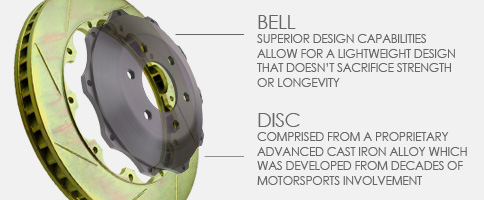

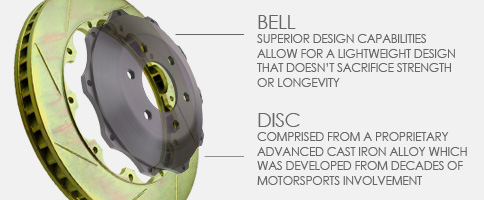

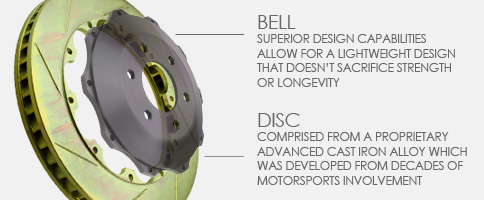

Brembo 2-piece discs are made up of an advanced cast-iron alloy which offers an exceptional coefficient of friction and resistance to thermal shock and fatigue.

As the braking system's primary function is to dissipate heat, larger, more sophisticated discs are used in order to increase the fade resistance of the system. These discs are directionally vented for enhanced cooling, as well as drilled or slotted for improved consistency, continuously cleaning and refreshing the pad surface.

By manufacturing the center section out of precision milled billet aluminum, a great deal of weight can be saved in this key location. This reduces both unsprung and rotating weight which benefits handling, acceleration overall vehicle dynamics.

Superior metallurgy and exceptional engineering allow Brembo discs to exceed in the most demanding conditions. Their advanced cast iron alloy lasts longer than any disc in the high performance and racing market.

Brembo discs are coated with zinc ("gold" color) to provide an attractive corrosive resistant finish.

Disc Thermal Capacity

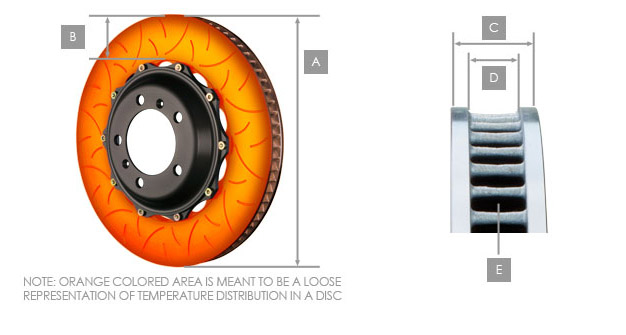

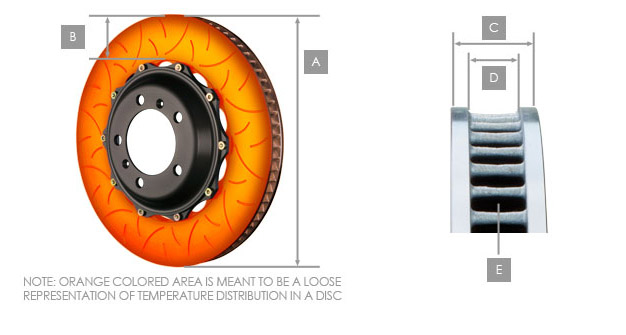

Brake systems are designed to operate best within a prescribed temperature range. While modern high performance friction materials broaden this temperature range, it is critical that the brake disc in a system has adequate thermal capacity.

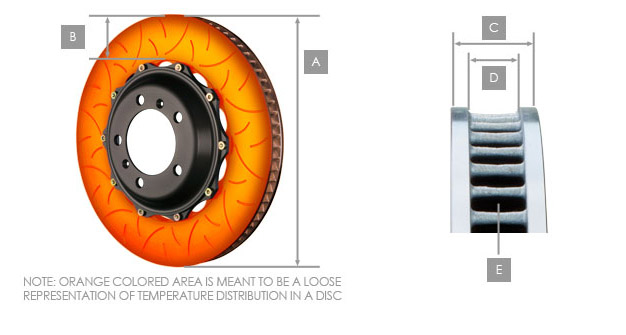

Thermal capacity, or heat storage capacity, is determined by how much weight or mass is located in the outer ring section of the disc. This is the area where the friction surface of the disc meets the internal vanes (orange colored area in the diagram shown). The more mass located in this area, the more thermal capacity a disc has.

Mass: The area located in the outer ring of the disc (shown in orange), dictates thermal capacity. This consists of annulus, width, diameter, air gap, and vane design.

Annulus: The area between two concentric circles. This dimension directly correlates to the friction surface area of the brake pad.

Disc Width: The overall thickness of the disc. Calipers are designed for a specific width.

Air Gap: The area located between the rotor plates surface is airgap. The amount of airgap is a crucial factor in channeling airflow.

Vane Design: Exclusive venting system that improves cooling capacity which increases resistance to brake fade.

Cross Drilled Discs

Cross drilled discs run at slightly lower temperatures due to added air flow through the surface of the disc where heat is generated.

They are also highly effective in wet conditions and shedding debris from the disc to ensure a clean braking surface. Improve pad "bite", improve wet weather performance, continuously refresh the brake pad

Slotted Discs

Slotted discs are recommended when using race pad materials or compounds. the vehicle is submitted to extreme braking duties such as towing or hauling heavy loads.

Improve pad "bite", improve wet weather performance, continuously refresh the brake pad

Airflow and Cooling

The curved vane disc is directional, and curved vane disc must be installed with the vanes running back from the inside to the outside diameters in the direction of rotation. Orienting the disc in the manner creates a centrifugal pump. The rotation of the disc causes air to be pumped from the center of the disc, through the vanes, and out through the outside diameter of the disc. This greatly enhances the disc's ability to dissipate heat. Additionally, all of Brembo's slotted discs are directional, regardless of the vane geometry. The discs should be installed such that the end of the slot nearest the outer edge of the disc contacts the pad first.

TECH NOTE: It is a popular misconception that the cross drill pattern determines the direction of rotation of the disc. In truth, for an internally vented drilled disc, the geometry of the vanes dictates the direction of rotation.

High Performance Brake Pads

Each Brembo system is delivered with preloaded calipers. Brake pads are selected vehicle specific for high performance.

Hardware

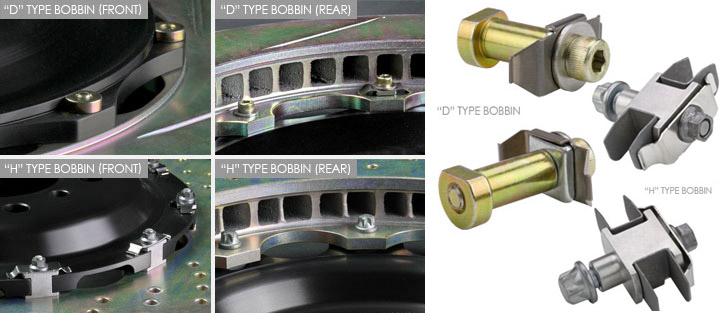

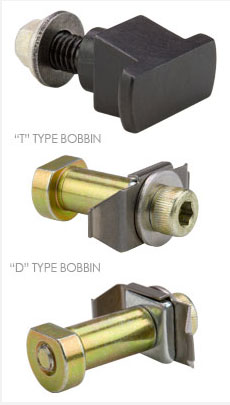

The coupling between bell, rotor and bushing has been carefully studied by Brembo to prevent performance and comfort problems by defining the correct tolerances for all components and the proper tightening torque.

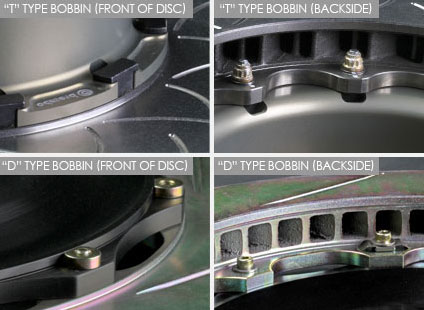

HOW IT WORKS

During braking, torque is transmitted from the disc to the bell through a fastener called a bobbin. This type of mounting system is designed to allow a specific amount of float in both radial and axial directions. This allows the disc to expand and contract under high temperature which reduces stress and increases longevity of the related components.

Brembo's unique anti-rattle disc hardware utilizes a spring fastener in order to slightly preload the assembly which eliminates the noise generally associated with floating discs.

The floating 2-piece anti-rattle disc hardware system, commonly used in high performance braking systems, was actually developed by Brembo back in the mid 90's.

This innovation was initially engineered exclusively for the McLaren F1 supercar which is why the hardware is often nicknamed the "McLaren" spring.

Brake Lines

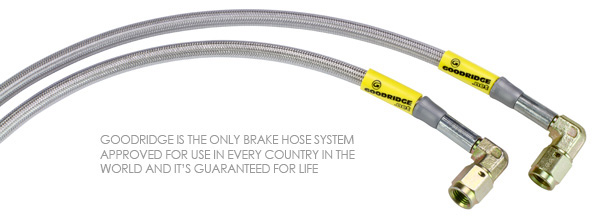

A set of Goodridge brake lines comes with every set of Brembo GT kit for your car. It's the only brake hose system approved for use by Brembo and it's guaranteed for life.

Goodridge is the leading line supplier to OE manufacturers and championship winning race teams worldwide. With the tightest bend radius in the industry and the lowest rate of expansion, you can be assured that every inch of pressure from the pedal is transferred directly to where it counts - the caliper.

Goodridge High Performance Brakeline race-bred street brake lines are constructed from the finest quality hose, consisting of a PTFE inner hose covered by braided stainless steel. In addition to providing a more responsive and firm brake pedal by eliminating the "spongy" feel that often accompanies stock rubber brake lines, High Performance Brakelines are abrasion and corrosion resistant to stay good looking for a long time to come.

so... "what's stopping you?"

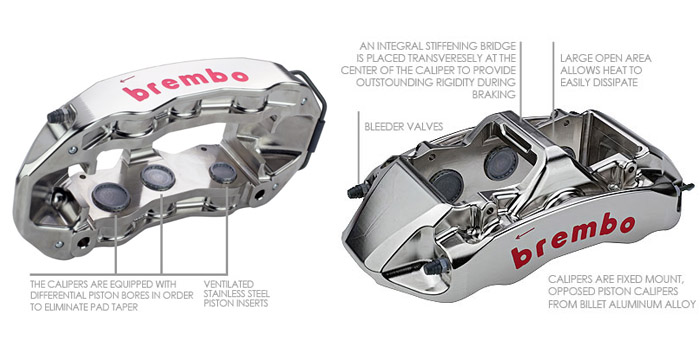

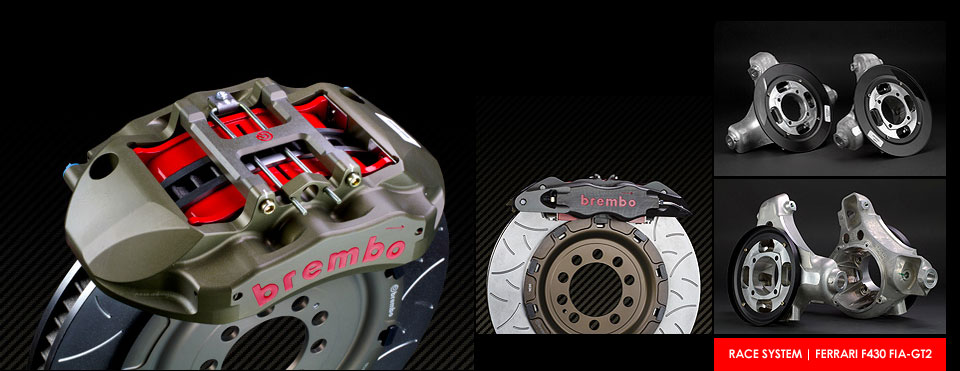

The GT-R (Grand Turismo Racing) System has been designed for the driver who demands exceptional performance on the street and on the track.

The GT-R monobloc calipers are machined entirely from billet with a nickel plated race finish to provide both the features and benefits of a racing brake system. This includes improved stiffness and thermo-mechanical resistance which is critical in high-performance applications.

The system includes 4 or 6-piston monobloc calipers, 2--piece floating brake disc assemblies, a selection of high performance or racing friction materials and all the necessary hardware to insure seamless installation.

200+ and still counting...

The Brembo High Performance (HP) Program is the direct result of winning over 200+ World Championships and decades of designing brake systems for the worlds top supercar manufacturers.

Brembo Dominated Motorsports: Formula 1, World Rally Championship (WRC), NASCAR, Champ Car World Series, Indy Racing League (IRL), American Le Mans Series (ALMS), Grand Am Rolex Sports Car Series, Speed World Challenge, and FIA GT Championship.

A Unique Experience

Brembo has a unique relationship working directly with automotive manufacturers to develop high performance braking solutions specifically for your vehicle. You can rest assured that every system designed by Brembo is specifically tuned for your vehicle like no other braking system on the market.

Brembo supplies over 30 automotive manufacturers including Acura, Aston Martin, Audi, BMW, Cadillac, Chrysler, Dodge, Ferrari, Ford, General Motors (GM), Honda, Infiniti, Jaguar, Jeep, Lamborghini, Land Rover, Lexus, Maserati, Mercedes-Benz, Mitsubishi, Nissan, Porsche, and Subaru.

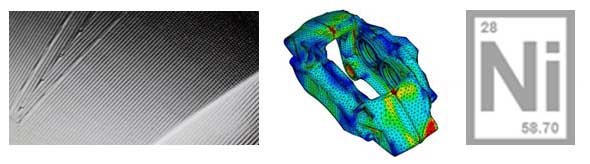

Brembo uses its own foundries in the industrial process, whereby bringing a thorough knowledge of metallurgy to its design know-how which also creates further synergy in the optimization of the production cycle. The research and development phase is flanked by the testing phase which involves static, comfort and road testing and dynamic tests on test benches.

Brembo brakes are manufactured under quality and environmental ISO 9004 and ISO 14000 management standards which puts Brembo in a league of its own in high performance braking.

|

System Includes (Per Axle) |

Caliper Construction / Material |

Number of Pistons |

Piston Design / Material |

Caliper Finish |

Disc Design |

Disc Type |

|

Calipers, Discs, Brake Lines, Caliper Mounting Brackets, and Brake Pads |

Billet 5-axis Machined, Aerospace Aluminum-alloy, Monobloc |

4, 6 |

Ventilated Stainless Steel Insert, Recessed Twin Seal |

Nickel Plated |

2-Piece |

Zinc Slotted, Zinc Cross Drilled, Type III or Type IV |

Effective Range of Brake Systems

Brembo High Performance GT Systems are designed to give you the advanced technology behind Brembo racing systems without compromising the driveability and comfort features of an OE Brembo system.

OEM (Non-Brembo) systems typically use a heavy, low-grade iron rotor and a flexible sliding caliper that severely limit performance.

Brembo OEM systems are superior to non-Brembo OE systems by the use of opposed, multi-piston aluminum fixed mount calipers, and high carbon discs.

Brembo High Performance (HP) GT & GT-R systems are revolutionary in their design and performance, and no other braking company has been able to offer this level of performance, range of configurations, and sheer number of applications. The GT & GT-R systems exemplify Brembo's dominance as a world leader in high performance braking as an OEM supplier to a winning partner in motorsports.

Racing systems are designed for the sole purpose of winning championships without compromise. This pinnacle of performance limits the ability to build in many of the comfort and anti-noise features that are built into Brembo GT and GT-R Systems.

Optimum Braking Performance

The technology and performance of a Brembo brake system is unrivaled by any other product on the market. Each bespoke system is desgined specific to your vechile for maximum performance and "optimum braking performance".

Brembo engineers design each brake upgrade specifically for your vehicle and driving conditions.

Optimum brake balance is achieved by combining Brembo's thorough knowledge of OEM braking systems and use of an unlimited range of caliper, piston, and disc combinations.

Brembo brake upgrades are easy to install and designed to work seamlessly with your vehicle's stock master cylinder, ABS, and traction control system.

Calipers

Brembo calipers are designed to be as light as possible while being uncompromised in stretch, durability and reliability.

Brembo calipers are equipped with unique pad retaining features and sequential piston bores in order to provide even pad wear and optimum performance.

GT-R's twin seal design provides race level performance without compromising the low maintenance aspects of a Brembo OE system.

Ventilated stainless steel piston inserts are incorporated for heat rejection.

The unique recessed dust seal design provides increased protection at elevated brake temperatures.

...another Brembo innovation.

Caliper Mounting Brackets

All Brembo caliper mounting brackets are designed vehicle and system specific. They are precision milled from superior quality billet materials to ensure a precise fit and meet the strength requirements of high performance driving conditions. Brembo brackets are also further analyzed and tested to ensure fatigue life.

Brembo caliper mounting brackets are also anodized to provide an attractive finish.

Each Brembo system includes all necessary hardware for ease of installation (please read instructions prior to installation).

Discs

2-Piece Discs

Brembo 2-piece discs are made up of an advanced cast-iron alloy which offers an exceptional coefficient of friction and resistance to thermal shock and fatigue.

As the braking system's primary function is to dissipate heat, larger, more sophisticated discs are used in order to increase the fade resistance of the system. These discs are directionally vented for enhanced cooling, as well as drilled or slotted for improved consistency, continuously cleaning and refreshing the pad surface.

Through Brembo's comprehensive understanding of materials and advanced design capabilities, Brembo's 2-piece discs are designed to be as lightweight as possible without compromising strength or longevity. Achieving this level of design is a capability that sets Brembo apart.

By manufacturing the center section out of precision milled billet aluminum, a great deal of weight can be saved in this key location. This reduces both unsprung and rotating weight which benefits handling, acceleration, and overall vehicle dynamics. Superior metallurgy and exceptional engineering allow Brembo discs to exceed in the most demanding conditions. Their advanced cast iron alloy lasts longer than any disc in the high performance and racing market.

Brembo's properitary floating hardware system permits a specific amount of radial and axial float which allows the disc to grow independent from the bell, averting thermal distortion when subjected to extreme temperatures. It also preloads the disc assembly to prevent premature wear and eliminate noise during street use.

Brembo's properitary floating hardware system permits a specific amount of radial and axial float which allows the disc to grow independent from the bell, averting thermal distortion when subjected to extreme temperatures. It also preloads the disc assembly to prevent premature wear and eliminate noise during street use.

Brembo discs are coated with zinc ("gold" color) to provide an attractive corrosive resistant finish.

Disc Thermal Capacity

Brake systems are designed to operate best within a prescribed temperature range. While modern high performance friction materials broaden this temperature range, it is critical that the brake disc in a system has adequate thermal capacity.

Thermal capacity, or heat storage capacity, is determined by how much weight or mass is located in the outer ring section of the disc. This is the area where the friction surface of the disc meets the internal vanes (orange colored area in the diagram shown). The more mass located in this area, the more thermal capacity a disc has.

Mass: The area located in the outer ring of the disc (shown in orange), dictates thermal capacity. This consists of annulus, width, diameter, air gap, and vane design.

Annulus: The area between two concentric circles. This dimension directly correlates to the friction surface area of the brake pad.

Disc Width: The overall thickness of the disc. Calipers are designed for a specific width.

Air Gap: The area located between the rotor plates surface is airgap. The amount of airgap is a crucial factor in channeling airflow.

Vane Design: Exclusive venting system that improves cooling capacity which increases resistance to brake fade.

Cross Drilled Discs

Cross drilled discs run at slightly lower temperatures due to added air flow through the surface of the disc where heat is generated.

They are also highly effective in wet conditions and shedding debris from the disc to ensure a clean braking surface. Improve pad "bite", improve wet weather performance, continuously refresh the brake pad

Slotted Discs

Slotted discs are recommended when using race pad materials or compounds. the vehicle is submitted to extreme braking duties such as towing or hauling heavy loads.

Improve pad "bite", improve wet weather performance, continuously refresh the brake pad

Airflow and Cooling

The curved vane disc is directional, and curved vane disc must be installed with the vanes running back from the inside to the outside diameters in the direction of rotation. Orienting the disc in the manner creates a centrifugal pump. The rotation of the disc causes air to be pumped from the center of the disc, through the vanes, and out through the outside diameter of the disc. This greatly enhances the disc's ability to dissipate heat. Additionally, all of Brembo's slotted discs are directional, regardless of the vane geometry. The discs should be installed such that the end of the slot nearest the outer edge of the disc contacts the pad first.

TECH NOTE: It is a popular misconception that the cross drill pattern determines the direction of rotation of the disc. In truth, for an internally vented drilled disc, the geometry of the vanes dictates the direction of rotation.

High Performance Brake Pads

Each Brembo system is delivered with preloaded calipers. Brake pads are selected vehicle specific for high performance.

Hardware

The coupling between bell, rotor and bushing has been carefully studied by Brembo to prevent performance and comfort problems by defining the correct tolerances for all components and the proper tightening torque.

Brake Lines

A set of Goodridge brake lines comes with every set of Brembo GT kit for your car. It's the only brake hose system approved for use by Brembo and it's guaranteed for life.

Goodridge is the leading line supplier to OE manufacturers and championship winning race teams worldwide. With the tightest bend radius in the industry and the lowest rate of expansion, you can be assured that every inch of pressure from the pedal is transferred directly to where it counts - the caliper.

Goodridge High Performance Brakeline race-bred street brake lines are constructed from the finest quality hose, consisting of a PTFE inner hose covered by braided stainless steel. In addition to providing a more responsive and firm brake pedal by eliminating the "spongy" feel that often accompanies stock rubber brake lines, High Performance Brakelines are abrasion and corrosion resistant to stay good looking for a long time to come.

so... "what's stopping you?"

The Racing calipers are forged and/or machined entirely from billet. Calipers are then treated with a clear hard anodized race finish. The combination of superior materials and a stringent manufactuting process maximize stiffness and thermo-mechanical resistance which is critical in racing.

The system includes 2, 4, or 6-piston monobloc or 2 piece calipers, 2-piece floating brake disc assemblies, a selection of racing friction materials and all the necessary hardware to insure seamless installation.

Brembo at-a-glance

|

The Brembo High Performance (HP) Program is the direct result of winning over 200+ World Championships and decades of designing brake systems for the worlds top supercar manufacturers. |

Brembo has a unique relationship working directly with automotive manufacturers to develop high performance braking solutions specifically for your vehicle. You can rest assured that every system designed by Brembo is specifically tuned for your vehicle like no other braking system on the market. |

Brembo uses its own foundries in the industrial process, whereby bringing a thorough knowledge of metallurgy to its design know-how which also creates further synergy in the optimization of the production cycle. The research and development phase is flanked by the testing phase which involves static, comfort and road testing and dynamic tests on test benches. |

Brembo race systems at-a-galance

System Includes |

Caliper Construction |

Number of Pistons |

Piston |

Caliper Finish |

Disc Type |

Disc Finish |

Calipers, Discs, Brake Lines, Caliper Mounting Brackets, and Brake Pads |

Billet 5-axis Machined, Aerospace Aluminum-alloy, Monobloc and 2-piece |

2, 4, 6, 8 |

Ventilated Titanium Insert, Single Inner Pressure Seal |

Clear Hard Anodized |

Slotted |

- |

Type III |

- |

|||||

Type V |

- |

Calipers

Forged monobloc calipers provide the ultimate in stiffness in regards to strength to weight ratio.

Brembo's calipers are a fixed radial or axial mount design with opposed pistons and constructed from forged and/or billet aluminum alloy.

Titanium has the highest strength to weight ratio of any metal. The low thermal condutivity and relatively high melting point makes it an ideal material for ventilated piston inserts.

Brembo calipers are equipped with unique pad retaining features and sequential piston bores in order to provide even pad wear and optimum performance.

Ventilated titanium piston inserts provide an additional barrier of heat protection (available in most race calipers)

High Performance Brake Pads

Each Brembo system is delivered with calipers preloaded with race pads. The pad compounds are selected based on unique variables related to the vehicle or racing environment.

Caliper Mounting Brackets

All Brembo caliper mounting brackets are designed vehicle and system specific. They are precision milled from superior quality billet materials to ensure a precise fit and meet the strength requirements of high performance driving conditions. Brembo brackets are also further analyzed and tested to ensure fatigue life.

Brembo caliper mounting brackets are also anodized to provide an attractive finish.

Each Brembo system includes all necessary hardware for ease of installation (please read instructions prior to installation).

Part numbers are clearly laser etched along with an unique serial number (S/N) for each part.

Pictured, are a few examples of axial and radial mount bracket designs.

Disc

2-PIECE DISCS

Through Brembo's comprehensive understanding of materials and advanced design capabilities, Brembo's 2-piece discs are designed to be as lightweight as possible without compromising strength or longevity. Achieving this level of design is a capability that sets Brembo apart.

By manufacturing the center section out of precision milled billet aluminum, a great deal of weight can be saved in this key location. This reduces both unsprung and rotating weight which benefits handling, acceleration, and overall vehicle dynamics.

Superior metallurgy and exceptional engineering allow Brembo discs to exceed in the most demanding conditions. Their advanced cast iron alloy lasts longer than any disc in the racing market.

Brembo's properitary floating hardware system permits a specific amount of radial and axial float which allows the disc to grow independent from the bell, averting thermal distortion when subjected to extreme temperatures. It also preloads the disc assembly to prevent premature wear.

Disc Thermal Capacity

Brake systems are designed to operate best within a prescribed temperature range. While modern high performance friction materials broaden this temperature range, it is critical that the brake disc in a system has adequate thermal capacity.

Thermal capacity, or heat storage capacity, is determined by how much weight or mass is located in the outer ring section of the disc. This is the area where the friction surface of the disc meets the internal vanes (orange colored area in the diagram shown). The more mass located in this area, the more thermal capacity a disc has.

Mass: The area located in the outer ring of the disc (shown in orange), dictates thermal capacity. This consists of annulus, width, diameter, air gap, and vane design.

Annulus: The area between two concentric circles. This dimension directly correlates to the friction surface area of the brake pad.

Disc Width: The overall thickness of the disc. Calipers are designed for a specific width.

Air Gap: The area located between the rotor plates surface is airgap. The amount of airgap is a crucial factor in channeling airflow.

Vane Design: Exclusive venting system that improves cooling capacity which increases resistance to brake fade.

Airflow and Cooling

The curved vane disc is directional, and curved vane disc must be installed with the vanes running back from the inside to the outside diameters in the direction of rotation. Orienting the disc in the manner creates a centrifugal pump. The rotation of the disc causes air to be pumped from the center of the disc, through the vanes, and out through the outside diameter of the disc. This greatly enhances the disc's ability to dissipate heat. Additionally, all of Brembo's slotted discs are directional, regardless of the vane geometry. The discs should be installed such that the end of the slot nearest the outer edge of the disc contacts the pad first.

TECH NOTE: It is a popular misconception that the cross drill pattern determines the direction of rotation of the disc. In truth, for an internally vented drilled disc, the geometry of the vanes dictates the direction of rotation.

Hardware

The coupling between the bell, disc and disc hardware has been carefully studied by Brembo to maximize performance, comfort, and longevity. These proprietary disc hardware systems were developed though extensive involvement in professional motorsports.

During braking, torque is transmitted from the disc to the bell through a fastener called a bobbin. This type of mounting system is designed to allow a specific amount of float in both radial and axial directions. This allows the disc to expand and contract under high temperature which reduces stress and increases longevity of the related components.

Brembo's unique anti-rattle disc hardware utilizes a spring fastener in order to slightly preload the assembly. This increases longevity and reduces excessive wear associated with floating discs.

Goodridge

Goodridge is the leading line supplier to OE manufacturers and championship winning race teams worldwide. With the tightest bend radius in the industry and the lowest rate of expansion, you can be assured that every inch of pressure from the pedal is transfered directly to where it counts - the caliper. Goodridge is the only brake hose system approved for use in every country in the world and it's guaranteed for life.

Goodridge brake lines are constructed from the finest quality hose, consisting of a PTFE inner hose covered by braided stainless steel. In addition to providing a more responsive and firm brake pedal by eliminating the "spongy" feel that often accompanies stock rubber brake lines, Goodridge brake lines are abrasion and corrosion resistant.